For all requirements

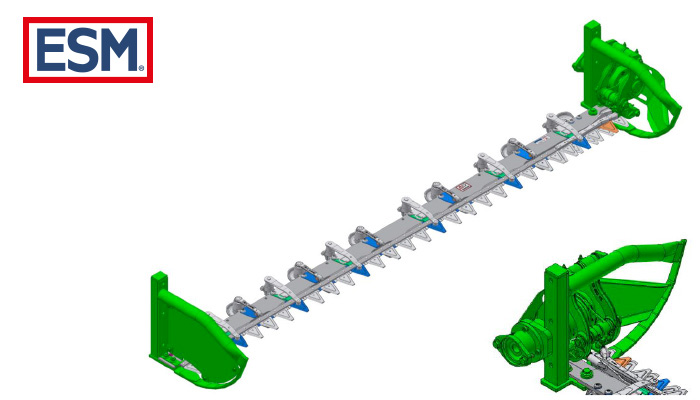

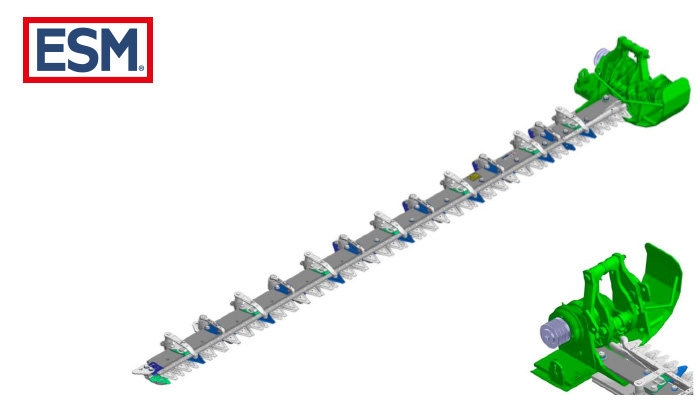

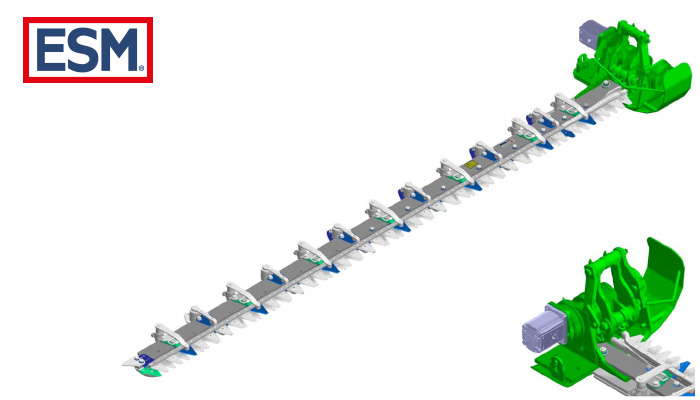

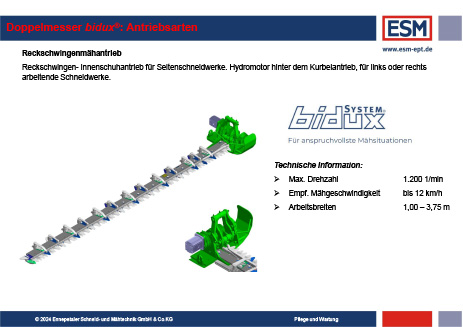

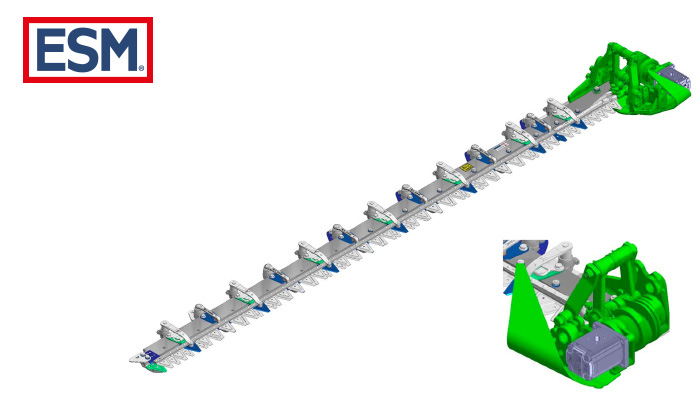

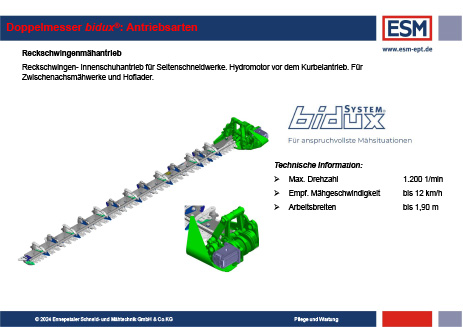

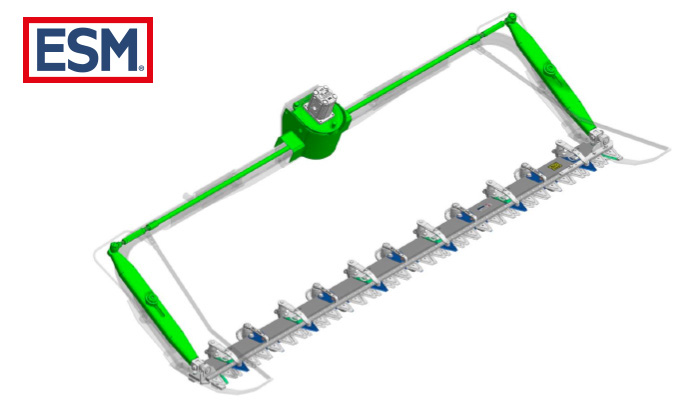

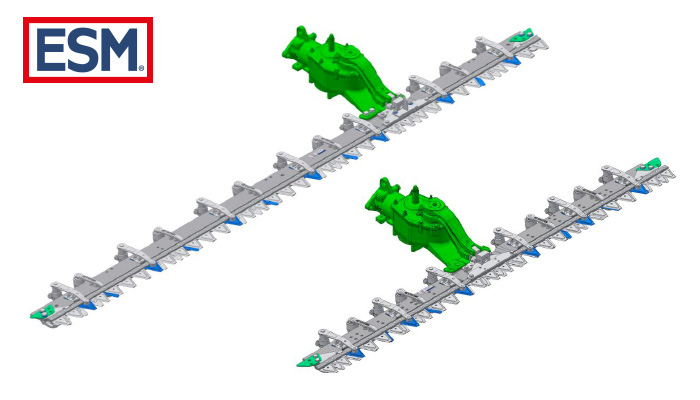

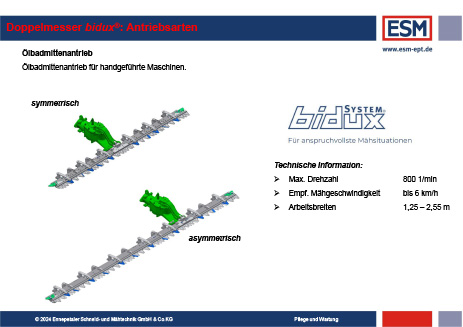

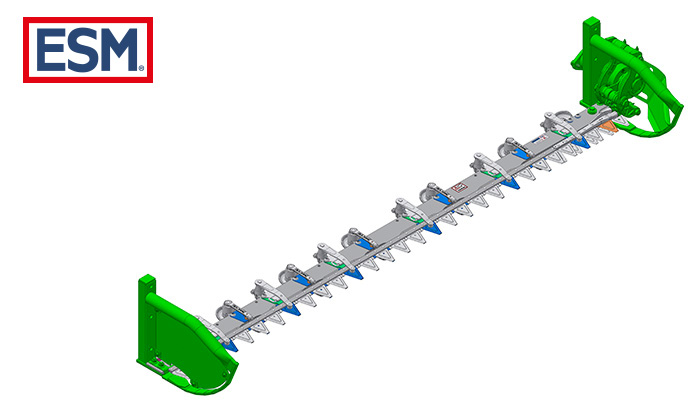

ESM double blade cutting system bidux®

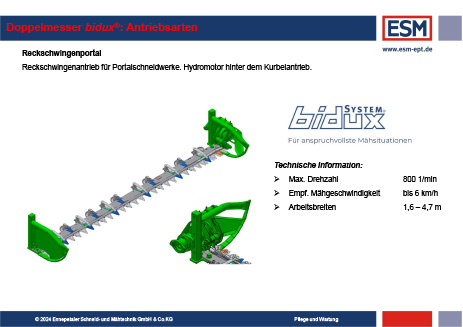

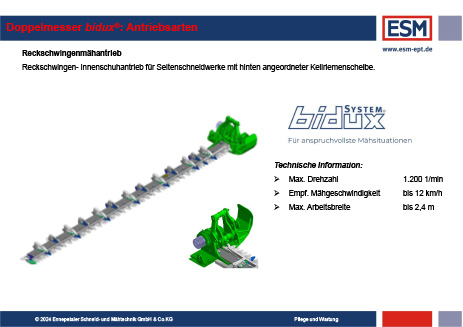

The "ESM bidux® double-knife cutting system", which has been tried and tested for decades and continuously developed, is a multi-tool that is suitable for every application.

Whether for forage harvesting, in demanding landscape maintenance or for countless special tasks: the "ESM bidux® double blade cutting system" always delivers unique work results.

An unrivalled, universal benchmark when it comes to obtaining clean forage, an important prerequisite for healthy livestock and therefore directly linked to the productivity and success of your farm.

Maximum protection of fauna, flora and habitats is guaranteed!

bidux® double-blade cutting unit

Videos

Sustainable grassland management with cutter bar mower

Brielmaier pick-up rake & Duo 6 | Demonstration in Schlins

Stöckl mower for Metrac 2017

Professional tip

Further product information

Practical tipsDescription | Document type | |

|---|---|---|

| Practical tips for double knife cutting units | Download | |

| Professional grinding of mower blades | Download | |

| Practical tips for double-blade cutterbars Busatis system | Download | |

| Beam reinforcement | Download | |

| CARBODUX® knife blade technology | Download the | |

| Rivet assortments | Download the | |

downloadDownload description | Document type | |

|---|---|---|

| ESM Service Station with guide rail | download | |

| Cause | Remedy |

| Blade is blunt | Grind or replace blade |

| Blade is not straight | Remove and straighten blade |

| Blades are not aligned | Straighten blades |

| Back of beam bent | Straighten back of beam |

| Play in blade guide too large | Adjust blade guides according to maintenance instructions |

| Speed and forward speed | At 1150 rpm approx. 10 km/h At 800 rpm max. 6 km/h (recommended guide values) |

| Cause | Remedy |

| Speed too high | Do not exceed the maximum speed of 1150 rpm! |

| Incorrect drive setting | Adjust according to user manual |

Variants, special shapes, specials

Only ESM has a serrated knife blade specially designed for use in coarse-grained material. This blade is used by bidux in the lower knife paired with a smooth upper knife for an exact cut, designed for maximum performance. Long service life and no regrinding necessary = reduction of grinding effort by 50 %. Only original from ESM!